Moulding

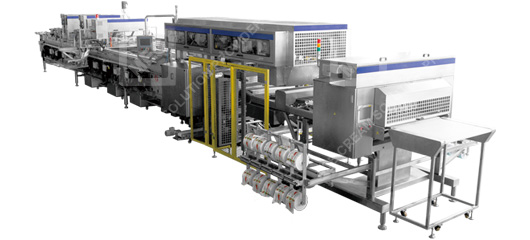

MEC moulding line enables flexible and efficient production of stick novelties such as ice cream, sherbet, ice water,that are formed and frozen in the mould.

Capacity Range: Up to 30000pcs/h

★ Actual capacity depending on product thickness, volume, mould shape, raw material inlet temperature, brine temperature, how many filling steps, recipe, capacity of wrapping solution, etc.

How MEC moulding line works?

Filling ice cream / ice water into the moulds;

Freezing product with low temperature brine bath;

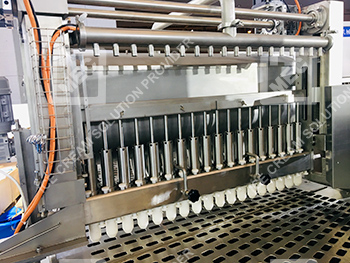

Insert wooden stick at the right time;

Defrosting a thin outer layer of product in a warm brine;

Extraction of the product from the moulds;

Chocolate coating;

Lay-off for packing;

MEC moulding production line is able to fit the different dispensing and decorating stations. The production capacity changes depending on the model, but the quality and flexibility remain the same. By changing the shape of ice-cream strip / roll moulds, you can produce multiple types of stick ice-cream on the same machine line.

MEC offers equipment for both ROTARY and LINEAR moulding production line, enabling flexible and efficient automatic continuous production of moulded ice cream stick nolveties, depending on the customer's priorities.

Why In-line / Linear moulding line?

Easy access to the plant;

Easier mould washing;

More flexibility for products change and variety;

Fast moulds changeover;

Why Rollo / Rotary moulding line?

Less brine consumption;

Less product waste;

Compact structure suitable compact space.

Main Features:

Gentle product handling and best hygiene design;

Fast mould / working stations change over for different products;

Increased efficiency and accurancy with servo-controlled mould, working station, extractor and product lay-off to wrapping.

Moulded Stick Novelties

Moulded Stick Novelties Extruded Stick Novelties

Extruded Stick Novelties Cones

Cones Wafer cup

Wafer cup Cups

Cups Bulk/ Family Pack

Bulk/ Family Pack Sandwich

Sandwich Bite sized & Candy bar

Bite sized & Candy bar Cake & Twister

Cake & Twister Ice water Squeeze-up

Ice water Squeeze-up

Tel:

Tel: WhatsApp:

WhatsApp: Mail:

Mail: