Filling

MEC ice cream filling production line can fill ice cream, ice water and sorbet products into cups, cones, squeeze-up tubes and bulk containers of varying design, shapes, sizes with customized decorations. No matter LINEAR or ROTARY type, there is always a model suitable for the space available in the factory.

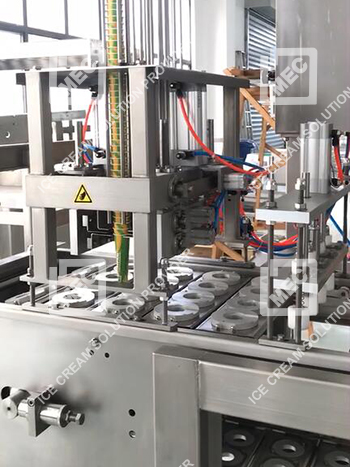

MEC linear ice cream filling machine is designed to meet the hygienic standards. The machine is supplied as standard for the production of one product type. Optional working stations are available for other product types and sizes. The linear movements of the lamella conveyors are synchronized. The unit is controlled via a PLC control system, enabling more accurate control. The basic machine, designed for one cup and one cone format.

Capacity Range:3000-20000pcs/h

Actual capacity based on detailed product type.

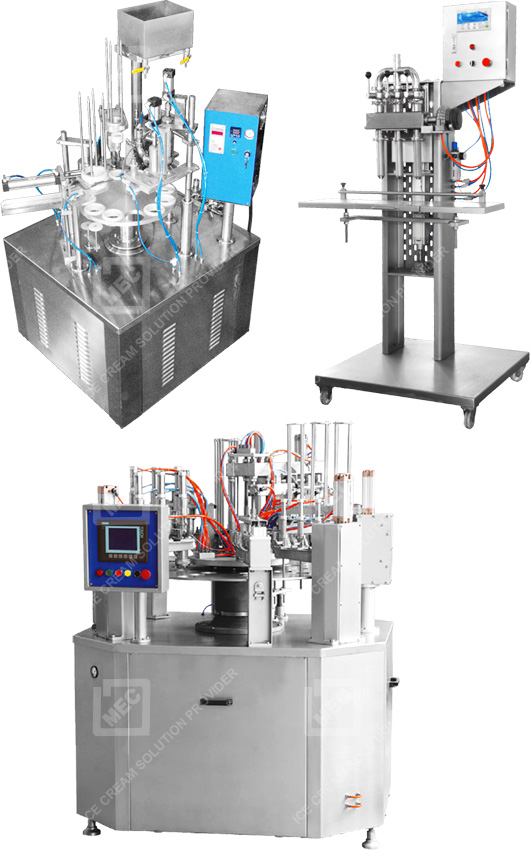

MEC rotary ice cream filling machine is built entirely in stainless steel. The rotating plate is made in one piece permitting easy access to the working stations and its smooth operation is ensured by a variable speed motor and an intermittent lubricated for life. All the basic movements of the machine are synchronized.

Capacity: 1500-3000pcs/h

MEC family pack filling machine is an ideal choice for making container ice cream (large volume), running in an intermittent linear manner, with two or three heads filling and bottling soft ice cream simultaneously. Easy to operate, convenient to move and multifunction including container discharging (by hand), filling, flower topping, jam charging, and products pushing out (by hand).

Capacity: 500-800pcs/h

Moulded Stick Novelties

Moulded Stick Novelties Extruded Stick Novelties

Extruded Stick Novelties Cones

Cones Wafer cup

Wafer cup Cups

Cups Bulk/ Family Pack

Bulk/ Family Pack Sandwich

Sandwich Bite sized & Candy bar

Bite sized & Candy bar Cake & Twister

Cake & Twister Ice water Squeeze-up

Ice water Squeeze-up

Tel:

Tel: WhatsApp:

WhatsApp: Mail:

Mail: